Benefits of EMI Filter Designs

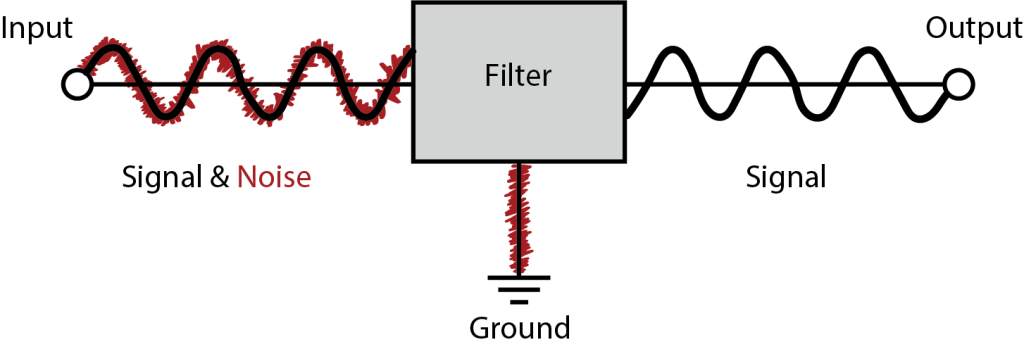

Noise is the downfall of all engineering design. Properly installed EMI filters suppress electromagnetic interference on power and signal lines, while allowing desired signals to pass. For critical EMI filter applications, high reliability is of hte utmost improtance. High reliability applications have diverse requirements, ranging from the need for long operating life in medical or military systems to consideration of the prohibitive cost of replacing a faulty component in a satellite, undersea cable, or other inaccessible system. High-Rel filters must satisfy applications-critical requirements in many different harsh environments: aerospace, satellites, military aircraft, missile systems, medical implantable, electronic warfare, precision instrumentation & measurement electronics, and electro-optics, among others.

Advantages of Solder-In Feed-Thru Filters

- Can be used in high density arrays or panels where tools cannot fit

- Used primarily to filter signal or data lines

- Can be used on AC lines

- Are effectively hermetically sealed with a true glass seal on one side

- Available in a press-fit case style when soldering is not desirable

- 610 Series filters have gold placed cases for optimum conductivity or solderability

Capacitor Elements:

Instec filters are manufactured using MLC discoidals. These robust capacitors provide optimum filtering and are preferred when compared to chip or leaded MLC capacitors and tubular capacitors . MLC discoidal caps have multiple electrodes and offer extremely low impedance due to the through-hole design of the discoidal cap providing infinite paths to ground. The discoidal design offers significantly lower inductance than leaded capacitor filters, lower impedance paths to ground than chip capacitor filters, and are much more robust in design than tubular capacitor filters. Discoidal caps design also effectively prevents radiation from the input coupling directly with the output of the capacitor, unlike leaded or chip capacitors used as filters. The combination of low impedance, low inductance, and input/output isolation provides excellent shunting of EMI for frequencies up to and beyond 1 GHz.

Instec discoidal caps also give the following advantages:

- Highest capacitance to volume ratio of the filter caps mentioned above.

- Lowest impedance at higher frequencies.

- Superior strength to tubular capacitors under both mechanical and thermal stresses.

Instec offers filters in various configurations as well as custom solutions. Selection of the proper filter for the application is key to achieving the best overall performance. Our design and technical teams are available to assist in this selection.

Resin Sealed Filters:

Instec Resin Sealed filters offer a wide variety of packages and sizes. These range from gold plated solder-in filters (610 Series) to 12-32 thread silver plated bolt filters (650 Series). The solder-in filters offer very low profile and narrow diameter filtering and are ideal for multi-circuits or filter plates where tight spacing is required. If the filters are to be used in a filter plate, Instec has a fine-tuned assembly process that can be used to assemble your filter plates. We are also set up to do 100% electrical screening and visual inspection on filter plates so your assembly yields would be pushed back to Instec.

The various sizes of bolt filters are ideal where higher current ratings are required or where inductive elements need to be introduced to the filter. All bolt filters ship with the required mounting hardware.

Note re. 610 Series solder-in filters: Instec solder-in filters have a hermetic seal on one side and the discoidal is soldered 360˚ around the OD. This combination, in effect, gives a hermetic seal with the chassis, wall or plate.

Hermetic Filters:

Instec Hermetic filters utilize glass seals to achieve hermeticity and are ideal for applications where rugged, sealed filters are required. Internal designs consist of combinations of capacitors and inductors (ferrite beads or wire-wound inductors) in ¼-28 or 5/16-24 threaded cases. Given their larger sizes, very high capacitances can be achieved and higher current ratings are possible. Filter performance can be tuned to match the application by choice of inductors.

Filter plates, custom assemblies, and solutions: Instec designers can work with your engineers to design custom solutions or to give you outsourcing options for your filter assemblies.